BLACKSBURG, VA. — Squeezing ketchup out of a packet and onto french fries is probably frustrating a restaurant customer at this moment. The ketchup that refuses to come out also is contributing to global food waste.

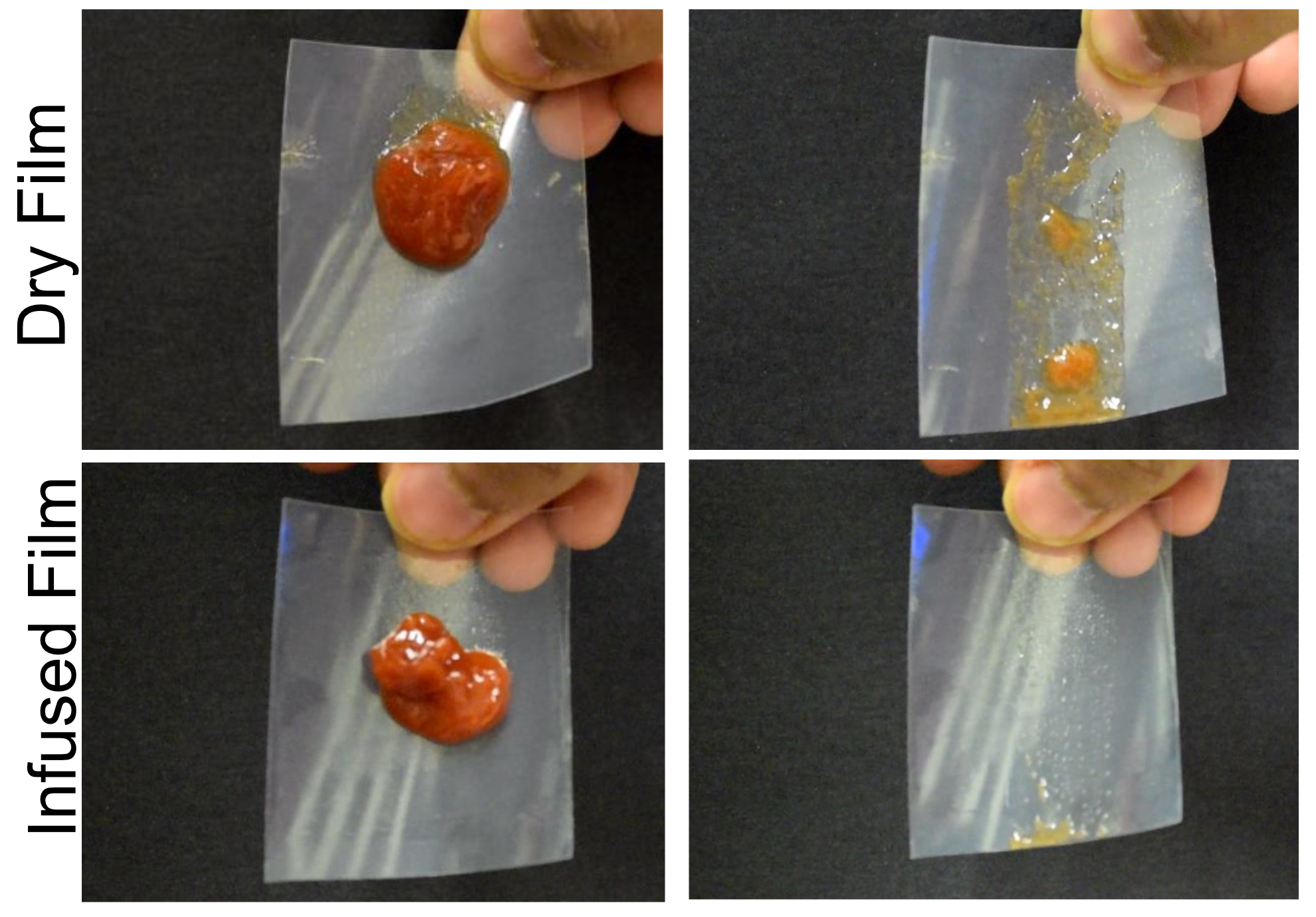

Researchers at Virginia Tech University in Blacksburg believe they have found a slippery solution to this ketchup conundrum. They have established a method for wicking chemically compatible vegetable oils into the surfaces of common extruded plastics. The technique causes sticky foods like ketchup to release from their packaging more easily.

A study published online Aug. 3 in Scientific Reports has yielded a provisional patent. The study may be found here. A video may be found here.

Courtesy of Virginia Tech University

“We’re not adding any mystery nanoparticles to the surfaces of these plastics that could make people uncomfortable,” said Jonathan Boreyko, Ph.D., an assistant professor of biomedical engineering and mechanics at Virginia Tech University and a study co-author. “We use natural oils like cottonseed oils so there are no health concerns whatsoever. There’s no fancy recipe required.”

The technique may be applied to plastics such as polyethylene and polypropylene, which are hydrocarbon-based polymers. The technique thus could be more cost-effective than using current slippery liquid-infused porous surfaces (SLIPS), which have been shown to hold a chemically compatible oil within their surfaces via the process of wicking.

“Previous SLIPS, or slippery liquid-infused porous surfaces, have been made using silicon- or fluorine-based polymers, which are very expensive, but we can make our SLIPS out of these hydrocarbon-based polymers, which are widely applicable to everyday packaged products,” said Ranit Mukherjee, a doctoral student in the university’s Department of Biomedical Engineering and Mechanics and the study’s lead author.

Courtesy of Virginia Tech University

SLIPS previously needed nano- or micro-roughness to keep the oil in place by way of surface tension. Surface material roughened with a type of applied coating achieved the needed roughness as did an absorbent polymer.

“We had two big breakthroughs,” Dr. Boreyko said. “Not only are we using these hydrocarbon-based polymers that are cheap and in high demand, but we don’t have to add any surface roughness either. We actually found oils that are naturally compatible with the plastics. So these oils are wicking into the plastic itself, not into a roughness we have to apply.”