Imagine a world where foodborne illnesses are dramatically reduced, and the freshness and quality of your favorite products are enhanced - all with the help of a single, powerful disinfectant. Welcome to the transformative era of chlorine dioxide (ClO2) in the food and beverage industry! This game-changing sanitizer has been revolutionizing the way businesses maintain their hygiene and safety standards, offering a myriad of benefits that go above and beyond traditional cleaning methods: particularly for emergency remediation and post-construction needs.

Chlorine dioxide offers numerous advantages for food safety, including:

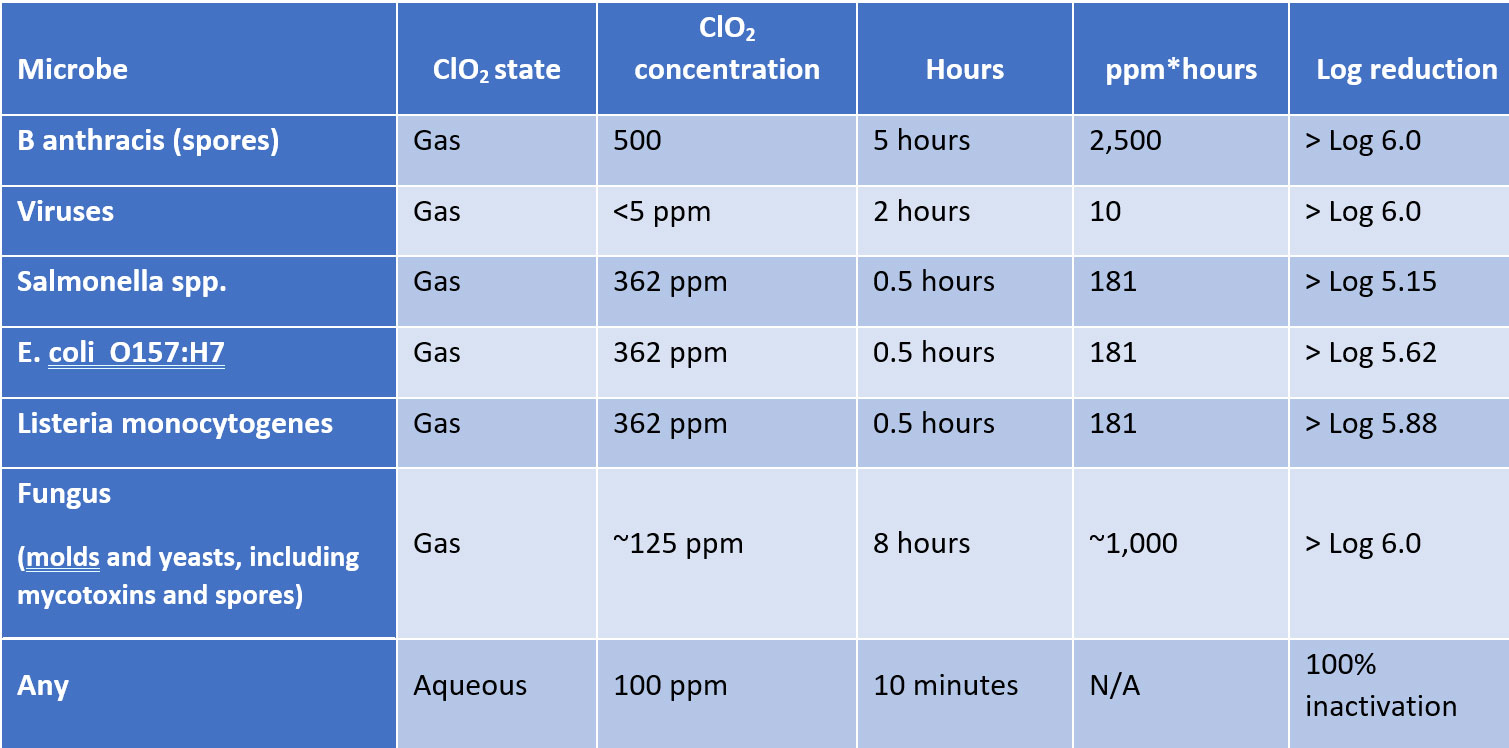

- Broad-spectrum antimicrobial activity: Chlorine dioxide is highly effective against a wide range of bacteria, viruses, fungi, and spores, ensuring comprehensive disinfection. With strong oxidation potential, ClO2 breaks down the cell walls of harmful microorganisms. 6-log reduction of pathogens are regularly achieved through chlorine dioxide, and chlorine dioxide solution provider PureLine guarantees 6-log reductions via all service treatments. See the below table for the inactivation properties of ClO2 for given microorganisms.

- Rapid action: It works quickly, eliminating pathogens in a short period, reducing downtime in your facility.

- Residue-free: Chlorine dioxide leaves no residue on surfaces or in the air, ensuring food safety and preserving the quality and taste of your products. This means no post-treatment cleaning necessary after using chlorine dioxide, whereas quaternary ammonium compounds (Quats) require such cleaning. Some chlorine dioxide products are OMRI Certified for Organic Use on food preparation surfaces due to being residue-free.

- Limited Material Compatibility Concerns: When compared to other chemicals, such as Peracetic acid, Quats, or hydrogen peroxide, chlorine dioxide gas poses less of a risk of corrosion to equipment.

Chlorine Dioxide Fumigation for Food Safety

One of the unique uses for chlorine dioxide for the food and beverage industry comes into play for larger scale bacterial remediation needs.

Usually after the construction of a new building, production line, or for emergency bacterial infection, chlorine dioxide fumigation can be utilized by food processors to reset the pathogenic environment. Chlorine dioxide gas is generated on site to treat all surfaces in buildings, rooms, or sealed equipment. This gives the food processor confidence of treating all surfaces and areas in which bacteria can be hiding. Upon de-gassing the treated space, no post-treatment cleaning is needed and production can resume.

PureLine offers mid-to-large scale chlorine dioxide fumigation services for companies going through new construction, or for emergency bacterial remediation. If your company needs to reset the pathogenic environment at your facility, you can fill out a contact form at PureLine’s website.