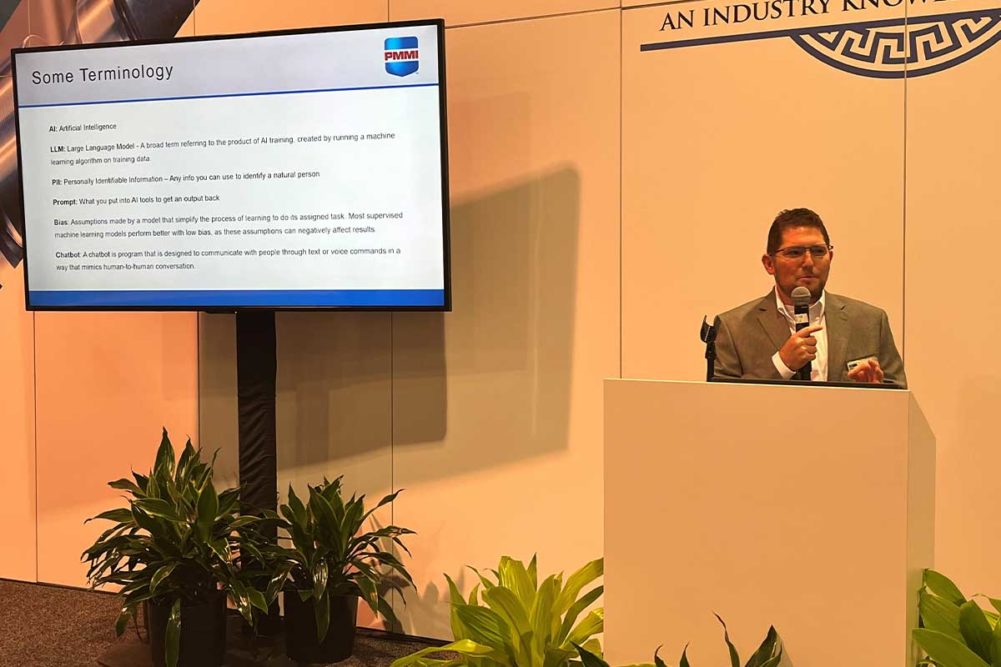

LAS VEGAS — Harnessing the power of artificial intelligence (AI) will be an important tool for manufacturers in the future, and those who begin exploring it now will have a leg up on competitors. That was the message from Andy Lomasky, senior director of IT for PMMI, the Association for Packaging and Processing Technologies, who spoke at Pack Expo Las Vegas, held Sept. 11-13 at the Las Vegas Convention Center.

Mr. Lomasky walked attendees of an expo session, “Exploring the Power of AI in Manufacturing,” through some basics of how AI may benefit manufacturers as well as some of its challenges and pitfalls.

“AI tools can make assumptions based on the information you put into it, and the output you get can sometimes come with a bias,” he said. “It’s something that you need to be aware of because AI is something that’s far from perfect. We’re on generation one right now. When I think about the lifecycle of technology, I like to think of it as crawl, walk and then run. I would say AI is pre-crawl right now. We’re still figuring it out.”

Andy Lomasky, senior director of IT for PMMI, spoke at a Pack Expo Las Vegas session.

Photo: Sosland Publishing Co.

Andy Lomasky, senior director of IT for PMMI, spoke at a Pack Expo Las Vegas session.

Photo: Sosland Publishing Co.

Artificial intelligence can help increase the efficiency in manufacturing, help personalize products, improve quality control and create smart factories by connecting machines and systems with seamless operation and real-time data analysis and optimizing production processes.

“How can AI empower manufacturers?” Mr. Lomasky asked. “It can help you increase efficiency. You can use AI and train it on your dataset using data from your equipment, your machinery on the floor. You can have AI reprogram equipment when it goes out of tolerance or when a sensor goes out of alignment. You can basically train it on a dataset and have it make proactive adjustments based on changes to that dataset.”

He suggested several policies and guidelines companies should consider before implementing AI, such as data privacy concerns, implementing robust cybersecurity measures and carefully monitoring all AI outputs for errors.

“With the Internet of Things and the ability to connect to pretty much anything, you’re only going to want to be more careful about how you connect these things,” Mr. Lomasky said.

Releasing personal information is a risk with AI. If a company inputs information that is released, it constitutes a data breach, something no company wants to be associated with.

“Thinking about confidential data and ensuring that you have the proper controls over how that data is used in an AI platform is absolutely critical,” he explained.

Mr. Lomasky urged manufacturers to begin exploring the technology by trying it out in small ways.

“Start small,” he said. “You don’t have to tackle connecting your entire shop floor to AI after a first go around. Maybe you just want to use it to write a marketing article on your website for one of your products. Just start small with simple use cases. Start learning. To me that’s the most important thing. Start with a small and simple use case and learn what it takes to make it a little better the next time. And make it iterative. Make it a process where you continuously learn and improve.”